The intensity of the heat treatment, sterilization or pasteurization, is expressed in the form of a Sterilizing Value (commonly called sterilization value or SV), or a PasteurizingValue (more often called pasteurizing value ou PV). This value equals the duration of the treatment leading to the decrease in the number of microorganisms when performed at the reference temperature.

What is Pasteurization Value (PV) ?

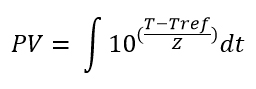

The Pasteurization Value corresponds to the duration of the different stages comprising rise in temperature, plateau temperature and cooling, which are the necessary stages to cut the microbial load in the required proportions. It is expressed by the formula: Obvioulsy, the Tref and Z values are adapted to the microorganisms under scrutiny. Thus there are a great number of possible calculations of the Pasteurization Value depending on the Tref and Z values used.

Obvioulsy, the Tref and Z values are adapted to the microorganisms under scrutiny. Thus there are a great number of possible calculations of the Pasteurization Value depending on the Tref and Z values used.The two most frequently used are Tref=70 and Z=10°C and thus the targeted Pasteurization Value is generally of 1000 points or minutes for a 42-day shelf-life. As soon as you are out of this frame, it is necessary to specify the two applied Tref and Z values suited to your needs otherwise you may not reach the targeted PV.

What is Sterilization Value (SV) ?

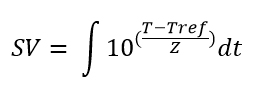

Sterilization is expressed in a time-equivalent (minutes or seconds) spent at the constant reference temperature. It describes the level of microbian destruction obtained by heat treatment. The result is expressed in minutes or, more exactly, in a minute-equivalent of exposure at 121,1°C (even if in some specific fields of application such as the sterilization of some medical instrument this SV can amount to higher temperatures).In other words, the sterilization value is the result of a calculation coming from a temperaturemeasured from the cold point of the product to be sterilized. The term « measurement of the Sterilization Value» which is generally used is therefore a misuse of language. The formula is the same as that of the pasteurization value:

By default, we consider that the Tref =121,1 °C and Z=10°C values are imposed for the calculation of this SV because they correspond to the optimal destruction of the reference germ named Clostridium Botulinum. Each product to treat having a specific microb load (that varies in type and volume), it is then appropriate to apply a suitable minimum sterilization value in order to guarantee industrial sterelity. This minimum sterilization process comprises the calculation of the sterilization value in which are included different detrimental factors linked to the sterilization process:

By default, we consider that the Tref =121,1 °C and Z=10°C values are imposed for the calculation of this SV because they correspond to the optimal destruction of the reference germ named Clostridium Botulinum. Each product to treat having a specific microb load (that varies in type and volume), it is then appropriate to apply a suitable minimum sterilization value in order to guarantee industrial sterelity. This minimum sterilization process comprises the calculation of the sterilization value in which are included different detrimental factors linked to the sterilization process:- conditions of packaging in the wrapping such as temperature, weight, pressure or gas volume

- how the autoclave equipment is framed and assembled - in order to determine the cold point of the autoclave

- what are the parameters of the autoclaving – taking into account critical load, critical maintenance point as well as critical battery power

Waranet Solutions expertise

PV or SV calculation accuracy is directly linked to temperature measurement. Temperature measurement errors have three main causes:- how the probe is positioned (the main cause of errors)

- how the probe is designed in terms of geometry and dimensions (related cause of error)

- the accuracy of the probe (additional cause of error)

Armed with solid experience in this field, using Waranet solutions ensures a monitoring of your cooking processes (pasteurization or sterilization) enabling you to obtain a real-time alert when pasteurization value or sterilization value is reached thanks to a tailormade alarm management system that is perfeclty built into your manufacturing process.

Comments (0)